Hull

Dimensions and Weights

Hulls of all Registered Yachts shall have the following dimensions and weights:

Length overall 30 feet, 2-1/2 inches Waterline length 20 feet Beam 6 feet, 5-1/4 inches Draft 4 feet, 9 inches Displacement 4,600 lbs. (excluding sails, spars, rigging) Keel 3,080 lbs. The following tolerances shall be allowed:

- Hull displacement may be as much as 4% more or less;

- Weight of the lead keel may be as much as 1% more or less;

- Center of gravity of the hull may be as much as 3 inches horizontally and 1 inch vertically from the center of gravity shown in these Specifications;

- Center of gravity of the lead keel may be as much as 1 inch horizontally and 1 inch vertically from the center of gravity shown in these Specifications.

Alterations to Hull Prohibited

No alterations of any kind shall be made to the hull, deck, keel or rudder except as permitted herein. This prohibition includes alterations to the leading edge of the keel, the rudder fairing strips and the after edge of the rudder.

(See Specifications 1.3, 1.4, 1.5, 3.1)

Rudder Shape and Thickness

Interpretation (Tiller Materials)

The tiller may be constructed by anyone and shall be made from wood (solid or laminated) and be of the size and shape as originally manufactured.The procedure to measure a Shields rudder's shape is as follows:

Step 1 Stretch a string along the after edge of the rudder post, top to bottom Step 2 Starting at the top of the rudder measure down along the string and mark the string every fifteen inches (15") for three stations Step 3 At the top of the mark measure perpendicular to the mark (90 degrees to the string) a distance of 10-9/16 inches and mark - Reference point 1 Step 4 At the middle mark measure perpendicular to the mark (90 degrees to the string) a distance of 12-3/4 inches and mark - Reference point 2 Step 5 At the bottom mark measure perpendicular to the mark (90 degrees to the string) a distance of 9-7/8 inches and mark - Reference point 3 Step 6 At each of the marks established in Steps 3 - 5 measure the thickness of the rudder: The thickness at each point shall be: No More Than No Less Than Reference point 1 .53" .48" Reference point 2 .57" .51" Reference point 3 .47" .42" From these reference marks to the trailing edge of the rudder, the rudder shall, in cross section, be neither a square nor the corner of a triangle. The rudder shall be fair with no hollows both between the reference points and from the reference points forward to the forward edge of the rudder. (See Specification 1.2 and 1.5)

Rudder Fairing Strips

The rudder fairing strips shall be made of bronze, plastic, or fiberglass. The fore and aft (true width) of the strips shall not exceed 1-1/2 inches.

Fairing

- "Fairing" is defined as long-board (batten) sanding, filling low spots, eliminating high spots and other "micro-smoothing" techniques used to achieve improved water flow over and around the hull. Fairing shall not alter the basic design shape of the hull, keel, rudder fairing strips or rudder. (See Specification 1.2 and 1.3)

- Fairing of the hull, keel, rudder fairing strips and the rudder is permitted in accordance with the definition of the term per the above and in accordance with Specifications 1.2, and 1.3. Further, an owner of a Registered Yacht shall:

- Notify the National Measurer of his intent to fair;

- Provide the National Measurer with a letter stating his compliance with Specifications 1.2, 1.3 and 1.4 after fairing; and

- Be prepared to withstand the cost of a professional measurement or survey if, in the opinion of the National Measurer and a majority of the Technical Committee, such measurement or survey is warranted.

- This Specification does not apply to the cost of a measurement or survey that might arise as a result of a protest under the Racing Rules.

- Annual maintenance that consists of filling and fairing the area where the hull meets the deadwood and the deadwood meets the lead casting is permitted. Filling, fairing and repairing damage incurred as the result of grounding is permitted. Such maintenance or repair does not require notification to the National Measurer.

- Any alteration of a Registered Yacht and the use of any li of equipment on a Registered Yacht, which is not expressly permitted herein, is prohibited.

Perforations - Hull/Deadwood

Perforations through the hull or deadwood to allow for drainage when the boat is out of the water are permitted. One through-hull perforation above the waterline is permitted for the exhaust of a bilge pump. (See Specification 10.1)

Perforations - Bulkheads

Perforations in the fore and aft bulkheads are permitted. Such perforations shall be made watertight while racing. One or two small holes not to exceed 3/8 inch in diameter may be drilled as close as possible to the top of the aft bulkhead to accommodate lines for trimming the backstay. (See Specifications 7.2, 10.1)

Bulkhead Hatches

While racing, fore and aft bulkhead hatches shall be in place. When in place, fore and aft bulkhead hatches shall be fully seated and secured against gaskets of soft rubber or its equivalent. Hasps of other devices may be replaced or altered to hold hatches in place more securely.

Stiffening Stringers

Addition of stiffening stringers forward of the forward bulkhead and aft of the after bulkhead is permitted.

Anti-fouling Paint

Anti-fouling paint shall be used on the bottom at all times.

Ballast

No ballast or dead weight shall be carried in the bilge. Normal gear and equipment may be carried therein.

Deck

Deck Supports

A wooden king post located between the mast partners and the forward edge of the cockpit is required. Further deck supports are permitted. The type of support(s) and their location is optional. This Specification is the basis for a tie-rod system and/or glass reinforcement in the area of the partners.

Mast Partners

- The mast partners shall be no more than 7-1/2 inches in the fore and aft direction.

- The aft edge of the mast partners shall be 9 feet 11-3/4 inches (+/- 3/4 inch) measured aft from the projected path of the headstay at the deck.

- The aft edge of the mast partners shall be 11 feet 3-3/8 inches (+/- 3/8 inch) from a vertical projection of the mooring line groove in the bow chock. The shape of the partners is optional. (See Specification 5.4)

Chainplates

The chainplates may be either L-shaped or inverted T-shaped. Alteration of L-shaped chainplates in accordance with Chris Craft's recommendation, dated April 1968, is permitted.

Toe Rail

The toe rail shall be in place, be made of wood and be nominally minimum 5/8 inch by 3/4 inch in any orientation as to height and width with allowances made for maintenance and age. Scupper holes may be used to facilitate deck drainage.

Control Console

A console made of wood or metal may be located between the mast and the forward edge of the cockpit coaming. It may be used as a base for a compass or as a base for cleats and blocks to assist in trimming the mainsail downhaul, Cunningham, spinnaker foreguy, topping lift, boomvang, jib sheets, fraculator or a combination of these. (See Specifications 7.3, 8.13, 8.14, 8.21, 8.24, 9.6, 10.4, 10.5, and Section V-5.3)

Rubrail

A rubrail is optional. The rubrail is defined as the layer of rubber, wood, or plastic material between the toe rail and the deck. (See Specification 2.4)

Perforations (Deck)

Perforations through the deck, between the bulkheads only, for the purpose of mounting equipment or leading control lines are permitted. One through-deck perforation in an air tank for the exhaust of a bilge pump is permitted. (See Specifications 7.2, 8.5, 8.16, 10.1, 10.5)

Backstay Gland

Interpretation (Preferred Fitting)

The preferred and recommended fitting for the backstay turning block is the part manufactured by Cape Cod Shipbuilding called "Backstay Deck Casting chrome plated bronze w/ sheave". This current design includes 4 mounting holes, a turning sheave, keeper pin and a gasket nut. Other combinations of parts may be used as long as they are of equivalent strength and are gasketed to be as watertight as practical.A sheave to turn the backstay pennant is permitted. Sheave must be gasketed to be as watertight as practical. (See Specifications 7.2)

Bow Chock

A bow chock of the original factory design with mooring line groove is required. The bow chock is part of the hull.

Foot Rails

[Proposed but not adopted.] Foot rails (two) shall be in place as part of the deck or added and roughly 1 to 2.5 inches tall by 3/4 inch wide and 52 to 54 inch long. They shall be located on the fore-deck centered in the mold marked foot rail deck area or approximately as shown in Official Plan 2 - Fittings and Rigging. There may be arched gaps in the foot rail in contact with the deck or other mechanisms to allow for optional jib tie-down straps.

Cockpit

Additions to the Cockpit

Additions within the cockpit for comfort or convenience such as cabinets, racks and steps are permitted.

Cockpit Seats

Two seats are required. They shall consist of no less than 6 slats, 1/2 inch thick, 1-1/2 inches wide and at least 50 inches long. Folding seats are permitted.

Hiking Strap Prohibition

No hiking straps or other device shall be rigged by any member of the crew for the purpose of supporting his weight outboard of the sheerline. (See Section III - 5.3 "Basic Rules")

Cockpit Floorboards

Interpretation (Construction)

Floorboards in the center sections aft of the kingpost (winch post) shall be made primarily of solid wooden slats. Surrounding the rudder post the floorboard shall be in place and may be constructed from either or both wooden slats or plywood. The floorboards forward of the kingpost post may be constructed from any material. In all cases the floorboards should be constructed to maintain the design as originally manufactured.Floorboards shall be neither altered nor removed for racing.

Cockpit Coaming

Interpretation (Clearances)

Clearance may cut from the lower edge of port and starboard coaming for winch handle and traveler and backstay controls.There shall be a wood cockpit coaming in place encircling the cockpit with a thickness of no less than 1/2 inch. The port and starboard coaming shall be no less than five (5) inches in height and projecting a minimum of two (2) inches above the deck. The aft coaming shall project a minimum of three-quaters (3/4) inch above the deck. The cockpit coaming may be strengthened by the addition of wood blocks or other materials.

Winches

Winches

Winches shall not be geared or be of the reel type. The maximum diameter of the rope-bearing portion of any winch drum shall be 3 inches.

Halyard Winches

There shall be at least two and not more than three halyard winches. Halyard winches may NOT be self-tailing. [NOTE: allowing self-tailing halyard winches was approved but then rejected by a fleet. Until further action self-tailing halyard winches are NOT allowed.] They shall be located below deck. The below-deck location of the halyard winches is optional. (See Specifications 4.1, 8.10 and Official Plan 2)

Sheet Winches

There shall be at least two and not more than four sheet winches, all of which shall be located on deck. Sheet winches may not be self-tailing. Handles for these sheet winches may be located above or below deck. Two sheet winches are required and shall be at the forward locations shown on Official Plan 2. Optional sheet winches may be located no less than 1 foot 8 inches or no more than 2 feet 6 inches, center to centerand adjacent to the coaming. Turning block or "ratchet" blocks may be installed in place of or in addition to the optional winches with their center anywhere in an area defined by the permitted location of the optional sheet winch centers fore and aft and athwartships from the outside of the coaming to the inside of the toe-rail. (See Specification 4.1 and Section VII - Official Sail Plans)

Mast

Masts may be rigged or fitted out by anyone but only in accordance with the Specifications and Official Plans 1 and 2.

Dimensions/Shapes/Weights

The dimensions, weights and shapes of the mast, boom and spinnaker pole shall conform to the Specifications and to Official Plans 1 and 2.

Fabrication of the Mast

Existing masts shall have been built only by Cape Cod Shipbuilding (Zephyr Products), Chris Craft Corporation or Henry Hinckley and Co. Only Zephyr Products shall build new masts.

Alternate Fabrication of the Mast

Masts may be fabricated in two parts. The lower part or section shall not be more than 2 feet long. A two-part mast, when assembled, shall in all other respects conform to the Specifications and to Official Plans 1 and 2.

Mast Blocks/Wedges

Masts may be blocked at the partners. Mast blocks or wedges shall not be changed or moved while racing. (See Specification 2.2)

Mast Weight/Center of Gravity

Completely stripped, masts shall weigh at least 75 pounds. The center of gravity shall be at least 18 feet from the heel of the mast.

Spreaders

Existing aluminum spreaders shall have been made only by Cape Cod Shipbuilding (Zephyr Products), Chris Craft or Henry Hinckley. Only Zephyr Products shall build new aluminum spreaders. Wooden spreaders are permitted. (See Section VII - Official Plan 2)

Mast Marking/Mast Band

A band, 1 inch wide and of a contrasting color shall be placed on the mast with the upper edge located 2 feet 5 inches above the deck at the centerline. While racing, no part of the mainsail shall extend below the upper edge of this band. (See Section VII - Official Plan 2)

Gooseneck Fitting

A fixed gooseneck attached to the mast is permitted. The manufacturer of the gooseneck fitting is optional. The location of the gooseneck is optional except that the top of the boom shall not be below the top edge of the marking band on the mast. (See Specifications 5.7, 6.1)

Standing Rigging

Interpretation (Equivallent Wire Types)

The use of Unidirectional lay wire (such as Dyform or compacted strand) has been determined to not be equivalent and its use is not allowed.Standing Rigging shall be of the types and sizes shown on Official Plans 1 and 2 and shall be fastened to the mast and hull only where shown in the Plans and only in the manner provided for in the Plans and in these Specifications. Use of "Sta-Master" brand turnbuckles has been ruled by the class to be prohibited. The headstay and upper and lower shrouds shall connect to the mast using marine eyes to through-bolted tangs.

Adjustment to the Standing Rigging

Adjustments to the headstay and the shrouds are prohibited while racing.

Mast Step

The mast step shall be located on the centerline of the boat and shall consist of an aluminum casting (as supplied by Cape Cod Ship Building) that is fastened to a fixed plate parallel to the deck by four machine screws through the central portion of the casting. After the effective date of this Specification, the mast step shall not be moved except under the supervision of a fleet measurer, who shall record the boat's Bury, Y and X dimensions after the step has been moved so as to be in a position to certify that the step location appears to be in conformity with this Specification. To compete in the National Championship Regatta a boat shall not move its mast step within 30 days of the commencement of the Regatta.

The maximum permissible forward position of the mast step shall be determined as follows:

- Measure the maximum permissible aft position of the after edge of the mast partners (135.75 inches aft of the mooring line groove in the bow chock, see Specification 2.2). Mark this position (PMax) on the deck at centerline.

- Measure the distance (Y) from the aft edge of the cockpit (on centerline at the surface of the deck behind the coaming, Point AC) to PMax.

- Measure the Bury, the distance from the surface of the deck (do not include any raised portion of a deck integrated partner box) at the aft most position of the partners to the surface of the mast step flange upon which the mast sits.

- Using dimensions of Bury and Y find the dimension X in Table X. X is measured from Point AC to the intersection of the aft edge of the mast where it rests on the step.

If the actual distance from point AC to the intersection of the aft edge of the mast where it rests on the step is greater than X, the mast step shall be moved aft sufficiently to comply with this Specification.

Table X : Shields Mast Step Location Guide: Defines Maximum X

Two (2) Degrees of Mast Rake with Partners at the Maximum Aft Position

All dimensions in Inches

Round off Bury and Y to nearest 0.25". Round 0.125", 0.375", 0.625", 0.875" Up.Bury\Y 133.50 133.75 134.00 134.25 134.50 134.75 135.00 135.25 135.50 135.75 136.00 136.25 136.50 136.75 137.00 33.00 138.63 138.87 139.12 139.36 139.60 139.85 140.09 140.33 140.58 140.82 141.06 141.30 141.55 141.79 142.03 33.25 138.70 138.94 139.19 139.43 139.67 139.91 140.16 140.40 140.64 140.89 141.13 141.37 141.61 141.86 142.10 33.50 138.77 139.01 139.25 139.50 139.74 139.98 140.22 140.47 140.71 140.95 141.20 141.44 141.68 141.92 142.17 33.75 138.84 139.08 139.32 139.56 139.81 140.05 140.29 140.54 140.78 141.02 141.26 141.51 141.75 141.99 142.24 34.00 138.91 139.15 139.39 139.63 139.88 140.12 140.36 140.60 140.85 141.09 141.33 141.57 141.82 142.06 142.30 34.25 138.98 139.22 139.46 139.70 139.95 140.19 140.43 140.67 140.92 141.16 141.40 141.64 141.89 142.13 142.37 34.50 139.05 139.29 139.53 139.77 140.02 140.26 140.50 140.74 140.99 141.23 141.47 141.71 141.95 142.20 142.44 34.75 139.12 139.36 139.60 139.84 140.09 140.33 140.57 140.81 141.05 141.30 141.54 141.78 142.02 142.27 142.51 35.00 139.19 139.43 139.67 139.91 140.16 140.40 140.64 140.88 141.13 141.37 141.61 141.85 142.09 142.34 142.58 35.25 139.26 139.50 139.74 139.99 140.23 140.47 140.71 140.95 141.20 141.44 141.68 141.92 142.16 142.41 142.65 35.50 139.33 139.57 139.82 140.06 140.30 140.54 140.78 141.02 141.27 141.51 141.75 141.99 142.23 142.48 142.72 35.75 139.40 139.65 139.89 140.13 140.37 140.61 140.85 141.10 141.34 141.58 141.82 142.06 142.31 142.55 142.79 36.00 139.48 139.72 139.96 140.20 140.44 140.68 140.93 141.17 141.41 141.65 141.89 142.14 142.38 142.62 142.86 36.25 139.55 139.79 140.03 140.27 140.52 140.76 141.00 141.24 141.48 141.72 141.97 142.21 142.45 142.69 142.93 36.50 139.62 139.86 140.11 140.35 140.59 140.83 141.07 141.31 141.55 141.80 142.04 142.28 142.52 142.76 143.00 36.75 139.70 139.94 140.18 140.42 140.66 140.90 141.14 141.39 141.63 141.87 142.11 142.35 142.59 142.84 143.08 37.00 139.77 140.01 140.25 140.49 140.74 140.98 141.22 141.46 141.70 141.94 142.18 142.43 142.67 142.91 143.15

Boom

Fabrication of the Boom

Booms may be rigged or fitted out by any person. The boom section may be fabricated by any manufacturer in conformance with the cross-sections used by Zephyr Products, Chris Craft and Hinckley. "Cut outs" to lighten the boom are prohibited except that the aft end of the boom may be partly cut on a diagonal with the underside of the diagonal cut left open. The boom must conform to this Specification, all other Specifications pertaining to it and its equipment and with Official Plans 1 and 2. (See Specifications 5.8, 6.2, 6.3, 6.4, 7.3, 7.4, 7.5, 8.1, 8.2, 8.7, 8.8, 8.18)

Length of the Boom

The length of the boom from the after face of the mast shall not exceed 13 feet 11 inches.

Boom Marking/Boom Band

A band, 1 inch wide and of a contrasting color shall be placed on the boom with the inner edge located 13 feet 3-5/8 inches from the after face of the mast. While racing no part of the mainsail shall extend beyond the inner edge of this band. (See Section VII - Official Plans)

Mainsheet Bail

A bail (stainless steel) for the Mainsheet turning block shall be located 12 feet 1-7/8 inches from the after face of the mast. (See Section VII - Official Plans)

Boom Sleeve/Reinforcement

A sleeve not to exceed 3 feet in length may be inserted in the boom or fixed to it externally in order to reinforce the area where the boomvang and/or mainsheet are located. (See Specification 6.1)

Backstay/Boomvang/Outhaul Adjustments

Adjustments

Adjustments of these controls shall be by manual hauling.

Backstay and Backstay Pennant

Interpretation (Materials)

The backstay is 1/8" stainless wire 1x19 and the backstay pennant is 5/32" stainless wire 7x19 or equivalent strength non-wire rope. The use of wire is recommended to maintain the integrity of the manufacturer's original grounding system. (See Section VII - Official Plan 2)The backstay may be led aft, amidships or forward. The purchase shall not exceed 8:1. The arrangement for turning the backstay pennant under the afterdeck is optional. (See Specifications 1.6, 2.8, 7.1)

Boomvang

The boomvang shall consist of a line or a combination of a wire leader or pennant attached to a line that runs through blocks. The purchase shall not exceed 8:1. The location of the attachment and the means of attachment to the boom, mast and/or console located between the mast and forward cockpit coaming is optional. (See Specifications 2.5, 6.1, 7.1 and Section VII - Official Plan 2)

Outhaul (Mainsail)

An internal outhaul and jiffy reefing "gear" is permitted in the boom. The purchase of the outhaul shall not exceed 8:1. Jiffy reefing tack hooks may be attached to the gooseneck. (See Specifications 6.1, 7.1 and Section VII - Official Plan 2)

Control Line Specifications

Mainsheet Trim Arrangement

Interpretation (Keeper)

Any device used between the mainsheet bail (#16 on Official Plan 2) and the mainsheet block(s) (#14 on Official Plan) to keep the mainsheet in place (such as a ring or rope loop) is optional and can be of any design.The location of block(s) and cleat(s) on the boom for adjusting the mainsheet is optional. The purchase of such arrangement shall not exceed 8:1 and may comprise a course and fine control. (See Specification 6.1 and Section VII - Official Plan 2)

Preventer

A single part preventer may be attached to the boom and to a shroud or chainplate. (See Specification 6.1)

Traveler Support

A support for the traveler track, made of fiberglass, wood or metal, may be mounted on the afterdeck. The support may be straight or curved and shall not extend beyond the inboard edge of the rubrail. The height above the centerline of the deck shall not exceed 1 inch. The height above the deck on the outboard ends of the support shall not exceed 3 inches. For a curved support, the chord dimension of the bend shall not exceed 4 inches. (See Specifications 8.4, 8.5)

Traveler

A straight or curved traveler track with a sliding car may be mounted on the traveler track support on the afterdeck. The track shall not extend beyond the inboard end of the rubrail. The types of track and car are optional. A metal tang or similar device may be mounted between the top of the track and the rubrail for the purpose of preventing the mainsheet from catching the end of the track while jibing. (See Specifications 8.3, 8.5 and Section VII - Official Plan 2)

Traveler Controls

Lines to adjust the traveler may be led above or below deck and may be trimmed amidships. The type of lines and control arrangement is optional. The purchase of such arrangement shall not exceed 8:1. (See Specifications 2.7, 8.3, 8.4)

Cleats

There shall be bow and stern mooring cleats. The type, number and location of all other cleats are optional. However, cleats shall not be of a type or in a location that will alter the lead of the main, jib or spinnaker sheets.

Blocks

The type and size of blocks for sheets is optional.

Shackles

The type and size of shackles is optional.

Halyards

Halyards may be of wire, wire/rope or rope only. Synthetic materials such as Kevlar or Spectra are permitted.

Jib Halyard Control

A jib halyard control-tensioning device other than the halyard winch itself is prohibited. (See Specifications 4.2 and Section V-6.2)

Spinnaker Halyard

The spinnaker halyard may have the return inside the mast and exit the mast at any location or be wholly outside the mast. When a halyard block is used the top of the sheave of the halyard block shall be at the same height as the spinnaker halyard fairlead as shown on Official Plan 2.

Spinnaker Pole

Interpretation (Storage)

Devices (such as brackets or lines) to store the spinnaker pole on or below deck are optional and may be of any design. Storage of the spinnaker pole on the boom or mast is prohibited.Spinnaker poles may be built by any person. The pole must conform to this Specification and Official Plans 1 and 2. The length of the spinnaker pole shall not exceed 9 feet 4 inches including fittings. It shall have a minimum diameter of 2 inches and excluding fittings shall be aluminum. Poles with a diameter in excess of 2 inches may be tapered to 2 inches at the ends.

Spinnaker Foreguy/Downhaul

The foreguy may be led either through the fairlead shown on Official Plan 2 or through or around the bow mooring cleat.

Spinnaker Pole Topping Lift

The topping lift may be rigged using fairleads, sheaves or blocks with or without mechanical advantage.

Spinnaker Pole Bridle

A bridle for the foreguy and the topping lift is optional. (See Specification 8.12 and Section VII - Official Plans)

Spinnaker Twing Lines

Twing lines are permitted.(See Specification 2.7)

Spinnaker Pole Mast Track

Alteration or replacement of the spinnaker track on the mast is permitted for the purpose of making the tracks stronger. There shall be no change in the length or location of the track. Adjustment of the spinnaker attachment ring shall only be done manually.

Spinnaker Sheets

Spinnaker sheets shall not be attached to the boom. Separate light sheets are permitted. Synthetic materials such as Kevlar or Spectra are permitted. (See Specification 8.7 and Section VII - Official Plan 2)

Jib Sheet Tracks/Carriage (Cars)

The makes of jib sheet tracks and carriages (cars) are optional, but only manually operated systems are permitted. (See Specification 8.20, 8.21)

Jib Sheet Carriage (Car) Controls

The jib sheet carriage (car) may only be moved manually while racing. (See Specification 8.19)

Jib Sheets

The jib sheets may be rigged with either one or two parts using one or both tracks. (See Specifications 8.7, 8.19, 8.20, 8.22, 8.23)

Reaching Leads

One reaching lead, port and starboard, may be located on the deck against the inboard edge of the toe rail. (See Specification 2.6)

Jib Sheet Carriage (Car) Track Placement

Interpretation (Both Tracks Required)

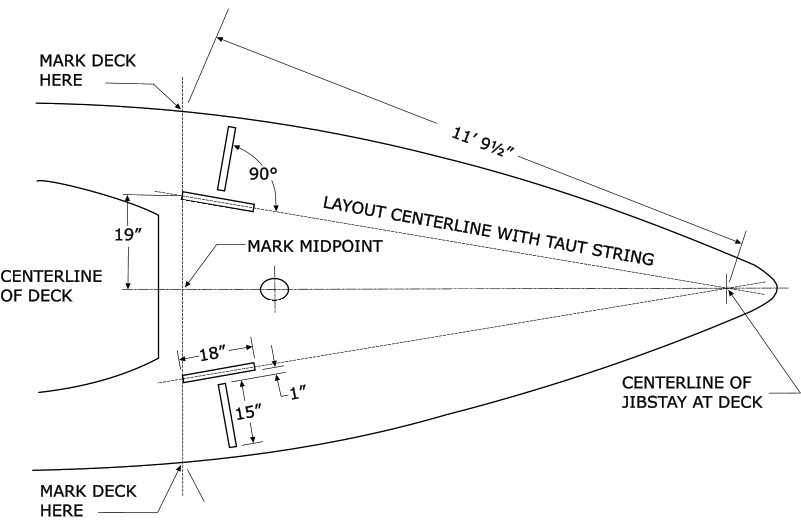

Both the ~8 degree/18" tracks and the thwartship/15" tracks are required even if not used.The jib sheet tracks shall be located on deck exactly as indicated below and in the following drawing (using the given dimensions and not the angle).

To position the track:

- Swing arcs from the centerline of the headstay 11 feet 9-1/2 inches to the deck at the sheer port and starboard.

- Connect the points thus established with a straight edge.

- Establish the centerline of the deck at the midpoint of this line.

- Establish the positions of aft ends of both ~8 degree tracks on this thwartships line 19 inches from centerline.

- Lay out centerline of ~8 degree tracks. Tracks shall be 18 inches long.

- Lay out centerlines of thwartship tracks from midpoints of the ~8 degree tracks at 90 degrees to them. Thwartship tracks shall be 15 inches long.

- There shall be a 1 inch clearance between tracks as shown in the drawing.

Figure 1: Jib Sheet Carriage Track Placement

Fraculator

A means of steadying the mast forward (especially downwind) is permitted but shall not involve additional attached fittings or blocks.Lines with hooks or clips attached to the stays, jib tack, jib luff, jib halyard or bow cleat are allowed and may lead back to the cockpit.

Mandatory Equipment

The following equipment shall be considered mandatory and shall be carried at all times:

Anchor

Interpretation (Equivalency)

A 13-pound Danforth anchor is a Danforth standard lightweight-type anchor, based on a design by R. S. Danforth and R. D. Ogg. Its nominal weight is 13 pounds. Its overall length (end of shank to bottom of crown) is 28-1/4"; its width (stock length) is 21-1/2"; and its fluke length is 14-1/2".

An equivalent anchor is one that is at least equal in value, function and effect to the 13-pound Danforth anchor. The relevant values, functions and effects of the 13-pound Danforth anchor are:

- Safety, i.e., setting characteristics and holding power;

- Utility, i.e., ease of deployment; and

- Weight and dimensions, i.e., the characteristics that affect ballast and stowage considerations while racing.

Holding-power is difficult to measure and compare, but the Danforth lightweight-type anchor is widely thought to have better setting characteristics and greater holding power in a broad range of conditions than other anchors of similar weight. An equivalent anchor must have at least the same or greater holding power before adding chain or rode. Although adding chain improves the holding power of a ground-tackle system, it does not make the anchor itself equivalent to the one with greater holding power, i.e., an anchor with insufficient holding power cannot be made equivalent by adding chain.

An equivalent anchor must be no more difficult to deploy. It must not require assembly from its stored condition before use; an anchor that is stored disassembled while racing in not equivalent.

An equivalent anchor must weigh 12 pounds or more when dry. But any modification of a 13-pound Danforth anchor that reduces its original weight makes that anchor not equivalent.

An equivalent anchor must have approximately the same or greater dimensions, e.g., shortening the stock or modifying the shank, crown or flukes so that the anchor may be stowed under the floorboards, or that is modified in any other way that diminishes its setting characteristics, holding power, ease of deployment, or weight is not equivalent.

One who uses another make of anchor has the burden of demonstrating that it has equivalent or greater holding power, weight and dimensions.

A 13-pound Danforth anchor or its equivalent and at least 100 feet of 1/2 inch nylon anchor line.

Lifejackets

One U.S. Coast Guard approved life jacket of suitable size for each person aboard plus at least one U.S. Coast Guard approved throwable device carried in an accessible place.

Paddle

A paddle or an oar at least 4 feet long must be carried on board at all times.

Sound Making Device

A horn, whistle or similar noise-making device as specified by the local Fleet when racing in local waters shall be carried on board at all times. A horn is required for the National Regatta unless this provision is waived by the local host Regatta Committee.

Pump

A pump and a sturdy 5 gallon (or two 2 1/2 gallon) bucket(s) suitable for bailing must be carried on board at all times.

Compass

A working compass must be on board at all times. An analog compass and/or self-contained electronic compass without GPS, memory or wind shift indications is allowed. The use of a built-in timer and "tactical" display mode can be used. (See Specification 10.5) Approved models include (other compasses must be approved by the Technical Committee):

- Tacktick model T060 Micro Compass

- Nautalytics Compass

- Velocitek Prism Racing Compass

Optional Equipment

The following equipment is optional and is permitted:

Bilge Pumps

Bilge pumps permanently mounted to the hull, portable hand pumps, additional buckets and other devices to facilitate self-rescue are permitted. One through-hull perforation above the waterline or one through-deck perforation is permitted for the exhaust of the pumps. One watertight perforation through a bulkhead for the run of the hoses and handles are permitted. The location of the pumps, the run of the hoses and the perforations mentioned herein are optional. (See Specifications 1.5, 1.6, 2.6, 10.15, 10.11)

Tiller Extension

A tiller extension or hiking stick is permitted.

Inclinometer

An Inclinometer is permitted. The location is optional.

Cunningham

A Cunningham is permitted.The arrangement of its control lines is optional.

Compass

Additional compasses are permitted. The location of all compasses is optional. (See Specifications 2.5, 2.7, 9.6)

Measuring Marks

Reference or measuring systems such as a ruler, ruled device or tape for determining the position of the backstay, outhaul, Cunningham, sheets and/or halyards is permitted. Such devices shall measure linear distance; they shall NOT measure tension. Location of such devices is optional.

Telltales

Telltales on sails and standing rigging are permitted. (See Section V - Sails 4.10)

Windex

Masthead wind direction indicator (fly) is permitted.

Electronic Devices

VHF radios, am/fm radios, radio cassettes, compact discs and other portable devices capable of playing music and receiving commercial radio and marine weather forecasts are permitted. Such devices shall not be used to communicate (transmit) individually with another party who is located ashore or on another vessel except in case of an emergency.

Prohibition: no electrically powered equipment is permitted other than that mentioned herein. Electronic instrumentation is not permitted.

The sailing instructions may change this rule to require VHF radios or other electronic devices.

Running Lights

Portable running lights are permitted.

Automatic Bilge Pump

An automatic bilge pump is permitted only when on the mooring.

Outboard Engine Brackets

Protrusions that might damage another yacht shall be removed while racing.

Spinnaker Container

A spinnaker bucket, turtle, fixed or movable bin to launch the spinnaker is permitted.